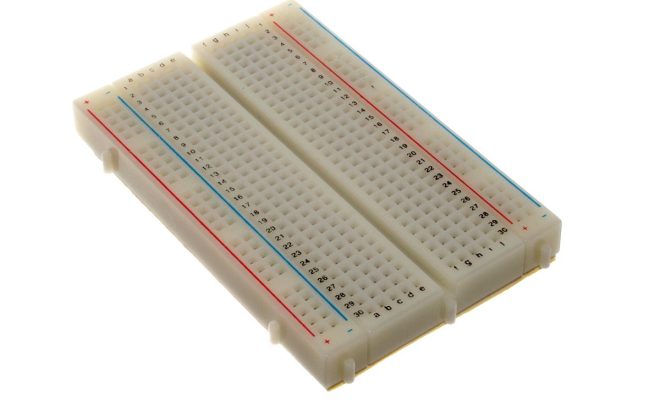

How Does a Breadboard Work?

A breadboard that is also known as a prototyping board or solderless breadboard is a fundamental tool that is used to make and test prototypes of electrical circuits. This tool is ideal for users who are looking to prototype or test electronic circuits fast without needing to go through the hassle of soldering components.

The simplest way to describe how a breadboard works is that it creates a temporary circuit by allowing you to insert and connect wires and various electrical components. They work by having a grid of small holes or pads made of metal that is arranged in a specific pattern. These small holes are designed to hold the leads of electrical components tightly into their spots. With the holes in these breadboards, it creates a socket where the components can easily be inserted. As a result, this creates a way to connect the leads of electronic components and experiment with the circuit without necessarily soldering all the components together.

Breadboards have two sets of holes or pads running down the center of the board, which are separated by a gap, often referred to as the “ditch”. The two halves of the board are electrically isolated, meaning that if you stick a wire into one half of the board, it will not connect with the other side unless you make an intentional connection.

The holes on the breadboard are connected to each other, hence the term “prototyping board”. The connections between each hole follow the pattern of the board. You will notice that each horizontal row of the breadboard is divided into five parts, and each of these parts is electrically connected. Along the bottom and top edges of the board are two horizontal rows that span the entire length of the board. These two lines are connected to positive and negative power rails respectively. By connecting these to an external power source, it can provide power to the components you are trying to prototype with.

In electrical circuits, it is essential to make connections that are solid and reliable. Breadboards make it very easy to do so without soldering, making it an ideal tool whether you are a novice or a seasoned electrical engineer. However, when you are working with high-frequency circuits or digital circuits, breadboards may not be the best solution since they may introduce noise or other signal problems.